News

Hot-Dip Galvanizing

June 1999 — Excerpt from the Westfalenpost

Prime Minister Wolfgang Clement is expected in Höingen this coming Saturday. He will visit the company Brinkmann located in the industrial park.

DM 10 million were invested by BRISTA’s president Dieter Brinkmann, which granted him one of the most modern galvanizing plants in Europe. With the initial operation of the new galvanizing plant BRISTA will be hosting an "open house" on June 19th, 1999. BRISTA wants to present the new eco-friendly technology to a wide audience.

"Growth is the natural desire of a healthy organism," says Managing Director Dieter Brinkmann. For this reason he transformed the company into a future-oriented company and is not afraid to make further rational investment.

For over 30 years, the family has been operating a galvanizing plant in Höingen. They work in three-shift operation at full capacity. "After initial operation of a conventional system, we installed the first continuous mining drag chain driven hot-dip galvanizing in the 1970s" said Dieter Brinkmann when speaking about the Höingen-based family operation, which is steeped in tradition. Galvanized material, mainly from the own production, allowed the decisive step in this direction.

"Growth and constantly evolving technology "were the basis for the investment in an additional galvanizing line. Rationality and environmental friendliness were priorities while planning and implementing this new hot-dip galvanizing plant.

Companies are challenged day by day. Especially with keeping up with the competition with the opening of the European market. And the tasks are growing daily.

Rising quality standards, flexibility and reliability are requirements in an efficient business relationship. "We are constantly striving to improve these requirements through active development steps," assures Dieter Brinkmann.

For BRISTA an environmentally friendly production is of utmost importance. Under these criteria they built the new galvanizing plant as an extension to the existing Plant 1.

"Our new galvanizing line already meets the future demands on an environmentally friendly, quick, cost effective and competitive production," explains Dieter Brinkmann during the test run.

1.5 million Mark alone were invested by BRISTA into environmental technology. The 160 employees operation provides a clean working environment and emissions-free work stations as areas exposed to acids are fully enclosed. "It is the most modern plant in Europe and we can soon galvanize up to 240 tons of steel per day," points Dieter Brinkmann out as the benefits of the 10 million investment. The system in the 4500 square meter factory building operates particularly energy and waste-limited. Dieter Brinkmann: "In the year 2002, the foreseen emission limits will be sinificantly lower than required by EU standards. Residues will be recycled and through heat recovery the energy utilization rate will be up to 96 percent. The Franz Brinkmann GmbH actually produces in harmony with nature, because the waste water is recycled in the base for new baths.

As a modern and environmentally friendly company BRISTA invested in the future.

Introduction

Introduction  History

History  Logistics

Logistics  Environment

Environment  News

News Archive

Archive  Career

Career  Profiling

Profiling  Robotic welding

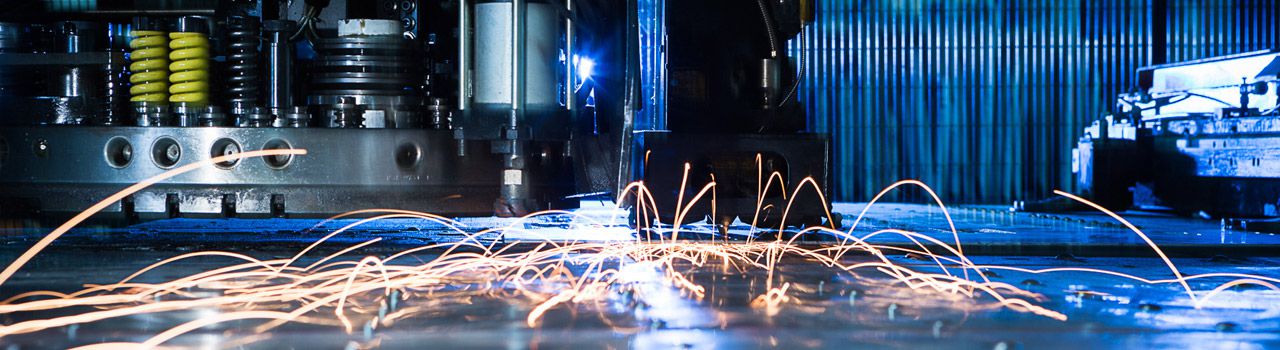

Robotic welding  Laser cutting

Laser cutting  Punching

Punching  Bending

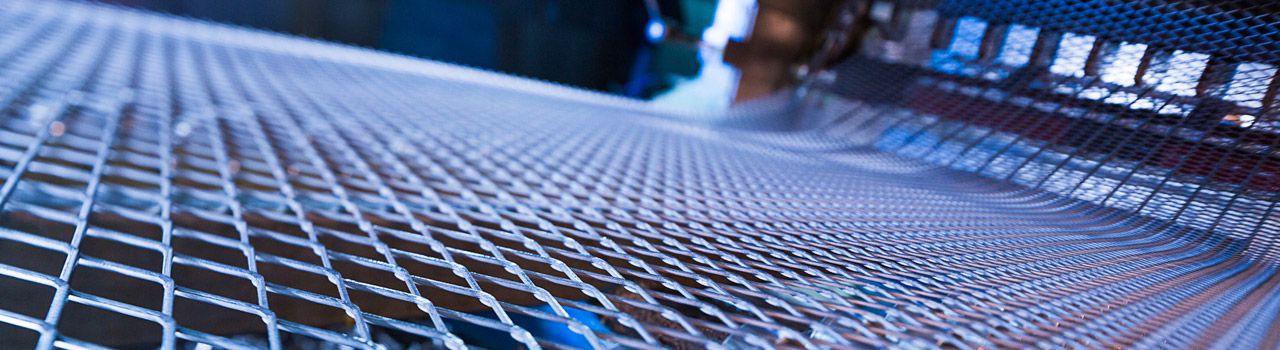

Bending  Expanded Metal

Expanded Metal  Hot dip galvanizing

Hot dip galvanizing  Powder coating

Powder coating  Double Stick Mats & Fence Covering Strips

Double Stick Mats & Fence Covering Strips Flatbar

Flatbar  Profile Rail

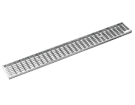

Profile Rail  Covering for Drainage Channels

Covering for Drainage Channels  Garden Range

Garden Range Screen for Wheelbarrow

Screen for Wheelbarrow  Attachment for wheelbarrow

Attachment for wheelbarrow  Planting Baskets

Planting Baskets  Connection Technology

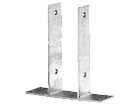

Connection Technology Post anchor H-shape

Post anchor H-shape  Post anchor U-shape

Post anchor U-shape  Post anchor L-shape

Post anchor L-shape  Angle connector

Angle connector  Perforated plate

Perforated plate  Expanded Metal Grates

Expanded Metal Grates  Stair Steps

Stair Steps Grating

Grating  Steel Basement Windows

Steel Basement Windows  Brista ArtPunch & Costum-made Products

Brista ArtPunch & Costum-made Products Contact and Directions

Contact and Directions  Downloads

Downloads  General Terms and Conditions

General Terms and Conditions  Navigation

Navigation